Trusted by

What is an IIoT solution?

Industrial IoT (IIoT) solutions monitor, collect, exchange, and analyze real-time sensor data from your equipment. They can perform advanced analytics and deliver meaningful shop-floor insights.

What is Industry 4.0?

Industry 4.0 refers to the integration of advanced technologies, like IoT, AI, and robotics, for enhanced manufacturing automation and industrial process connectivity.

Why do you need IIoT?

IIoT is easy to scale and deploy. It empowers organizations to:

- Derive insights from real-time data

- Monitor equipment and proactively prevent down-time.

- Drive rapid and continuous value for manufacturing units

- Leverage vertical expertise across the shop floor

- Improve shop floor efficiency and reduce costs

How do I get started?

- Fill out our Request Demo form

- We'll visit your site to assess your needs and existing hardware.

- Our team of experts will schedule a demo call and walk you through our platform and solutions

- We will propose a solution to suit your needs.

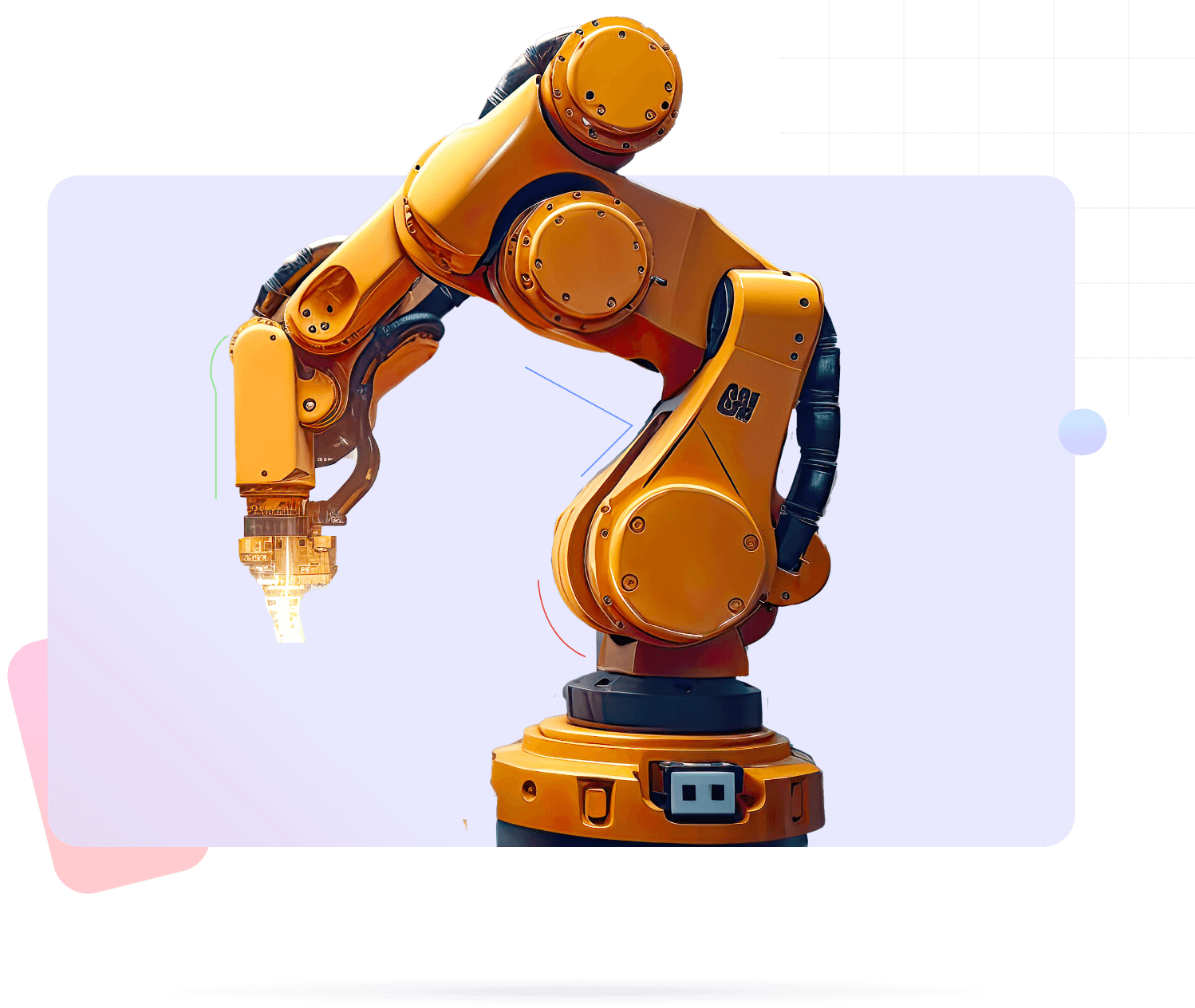

Intelligent shop floor automation

Industry 4.0 is just a click away. Whether you want to monitor one machine or automate your entire factory, we've got you covered. Explore Zoho's expansive multi-vertical IIoT solutions now.

Discrete manufacturing

- Construction and building materials

- Automobiles

- Aerospace and defense

- Machines and equipment

- Medical devices

- Appliances

- Electronics

- Automotive parts

Process manufacturing

- Chemical

- Food and beverage

- Oil and gas

- Pharmaceutical

- Metal and steel

- Glass

- Textile

- Adhesives and Paint

Discover Zoho's IIoT platform

- Connect seamlessly

Zoho's IIoT platform supports multiple brands and data collection protocols from both legacy and new machines. Generate actionable insights from a few units—or a few hundred.

- Collect data from devices and controllers

Plug and play with PLC/SCADA systems, sensors, gateways, supporting MODBUS, OPC/UA, RTU, MT Connect, Profibus, Profinet, Ethernet IP, and proprietary connectors for seamless integration with any third-party systems.

- Collect a range of data types

Monitor custom sensor values, machine statuses, modes, alarms, overrides, load averages, speeds, temperatures, rotations, PMC parameters, diagnostics, and more.

- Experience high-frequency data collection:

Perform real-time data collection at a high frequency (1 KHz) from specific CNC controls for immediate input into machine learning models.

- Configure and manage sensors

Improve your system by integrating external sensors or connecting older equipment using digital and analog input/output. Remotely configure and oversee sensors through an intuitive web interface.

- Brands we support

- Protocols we support

- Edge computing

Utilize the Zoho EdgeX edge computing solution for localized actions and data filtering. Refine data transferred for analytics, diagnose problems, and deploy updates to the edge without visiting sites.

- Secure data aggregation

Aggregate data collected from multiple sources. Our platform provides secure, scalable infrastructure for manufacturing data, featuring regular security updates and user-friendly data management tools.

- Telemetry and reporting

Sync diverse equipment data for consistent reporting and AI based analytics. You can evaluate custom sensor values, machine statuses, alarms, loads, speeds, and more.

- Remote management

Site visits can be tedious—Remotely manage and control your machines through Zoho EdgeX edge computing. Implement changes with the click of a button from any location.

- Secure cloud integration and storage

Using HTTPS/MQTT protocols, securely stream and store data from the edge to Zoho's IoT cloud infrastructure for quick and scalable data access.

- Integrate with other applications and APIs

Effortlessly integrate machine data with your digital factory by connecting it to existing shop floor systems. REST APIs enable integration with your CRM, ERP, BI tools, and other essential applications.

- Create workflows

Establish rule-based workflows for shop floor data, setting machine conditions and performance metrics, to prompt manual action or automate system responses.

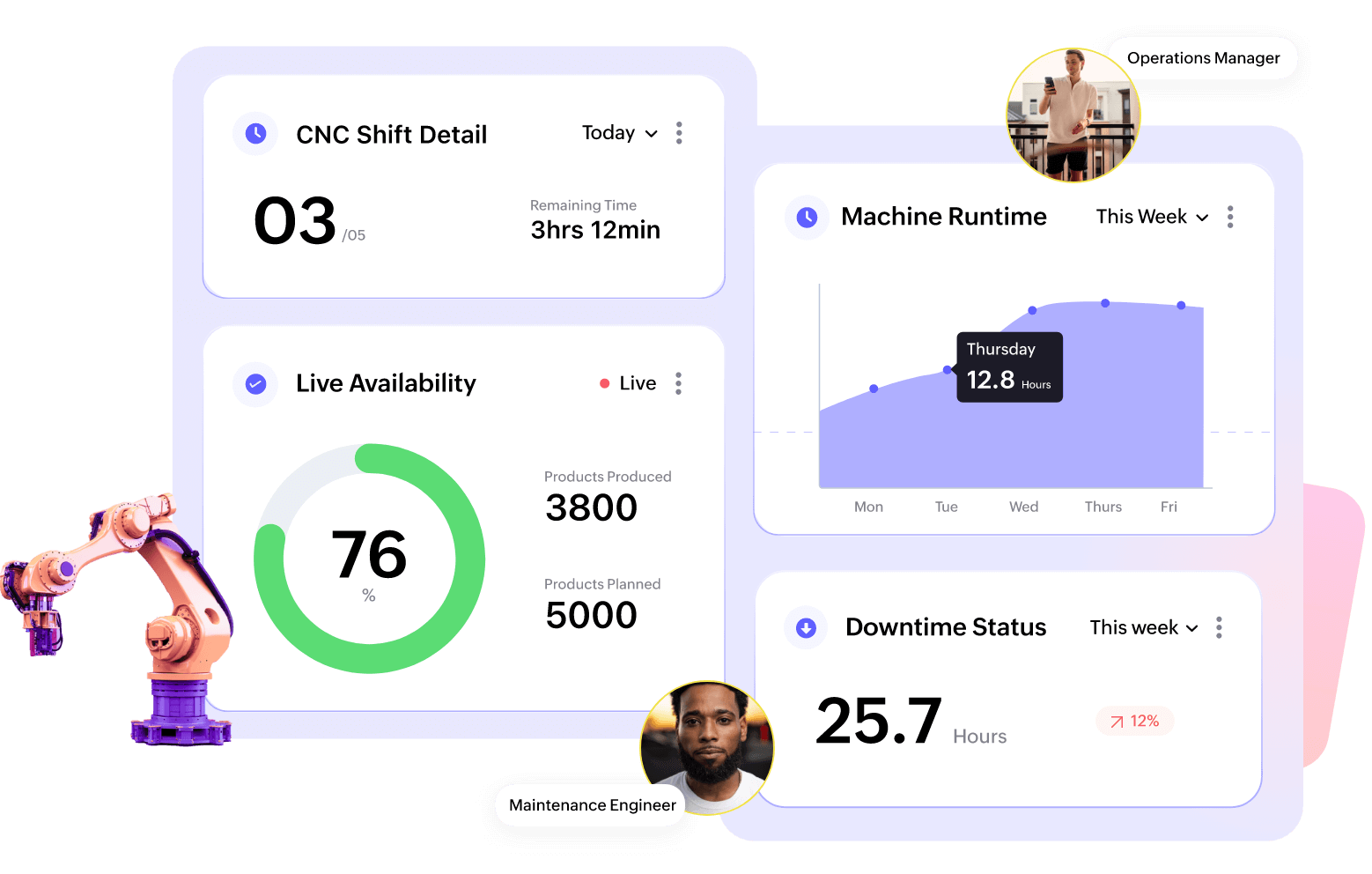

- Real-time insights

Provide service managers and technicians with status updates on equipment health through real-time and historical condition monitoring. Enable preventative maintenance by configuring anomaly notifications with color-coded severity.

- Integrate AI with analytics

With deep analytics provided by performance reports, identify bottlenecks, and assess OEE, machine utilization and downtime history. Gain visibility and derive actionable insights into every production line throughout your organization.

- Build your own IIoT solutions

Develop your own apps with customized UI. Then, integrate them with third-party applications for quality or inventory control, stake holder role customization, extension of current modules to accommodate various use cases, and more.

- Machine Monitoring

- Production Line monitoring

- Overall Equipment Effectiveness

- Shifts and Jobs Allocation

- Maintenance and SLA

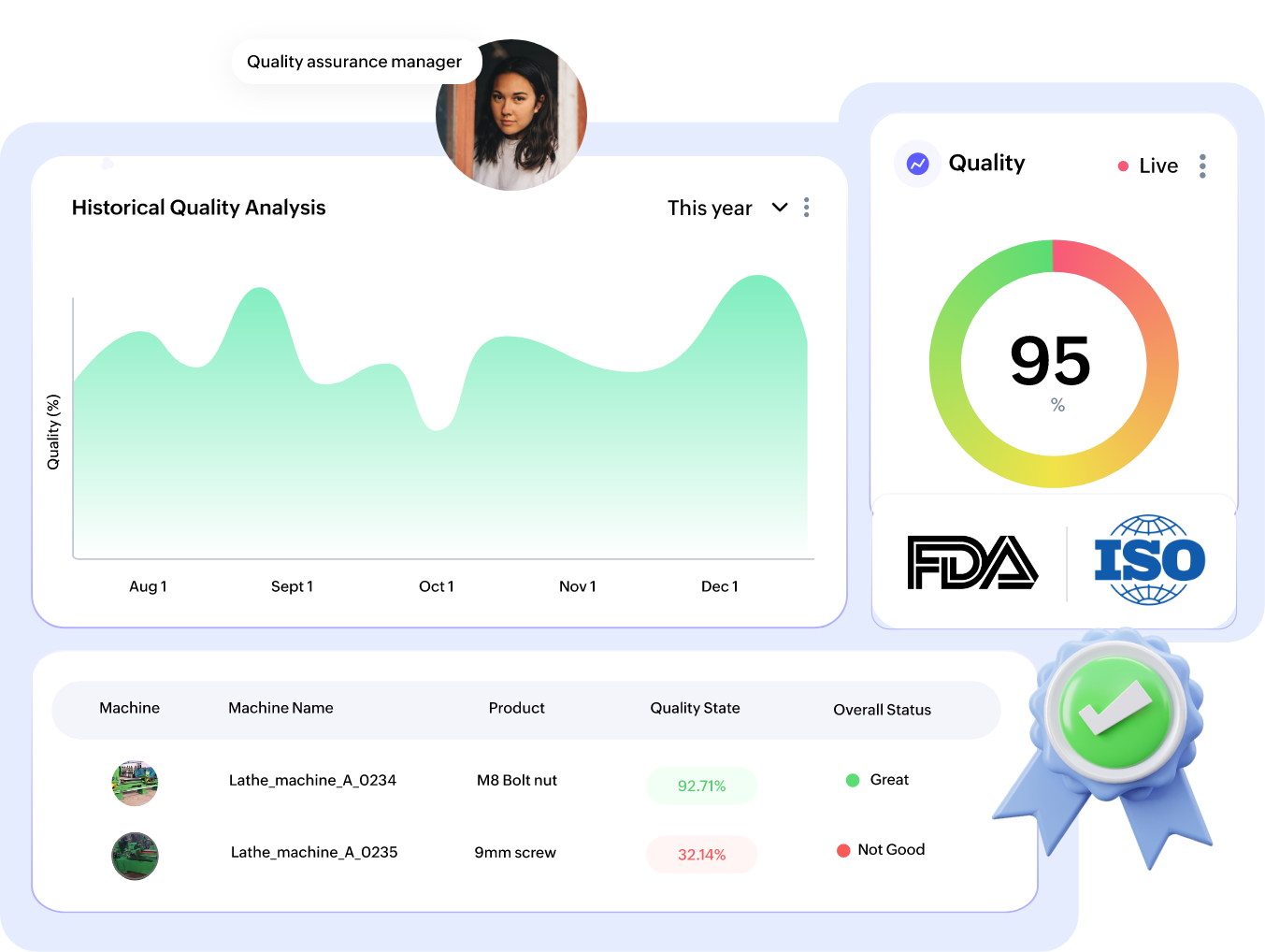

- Quality Analysis

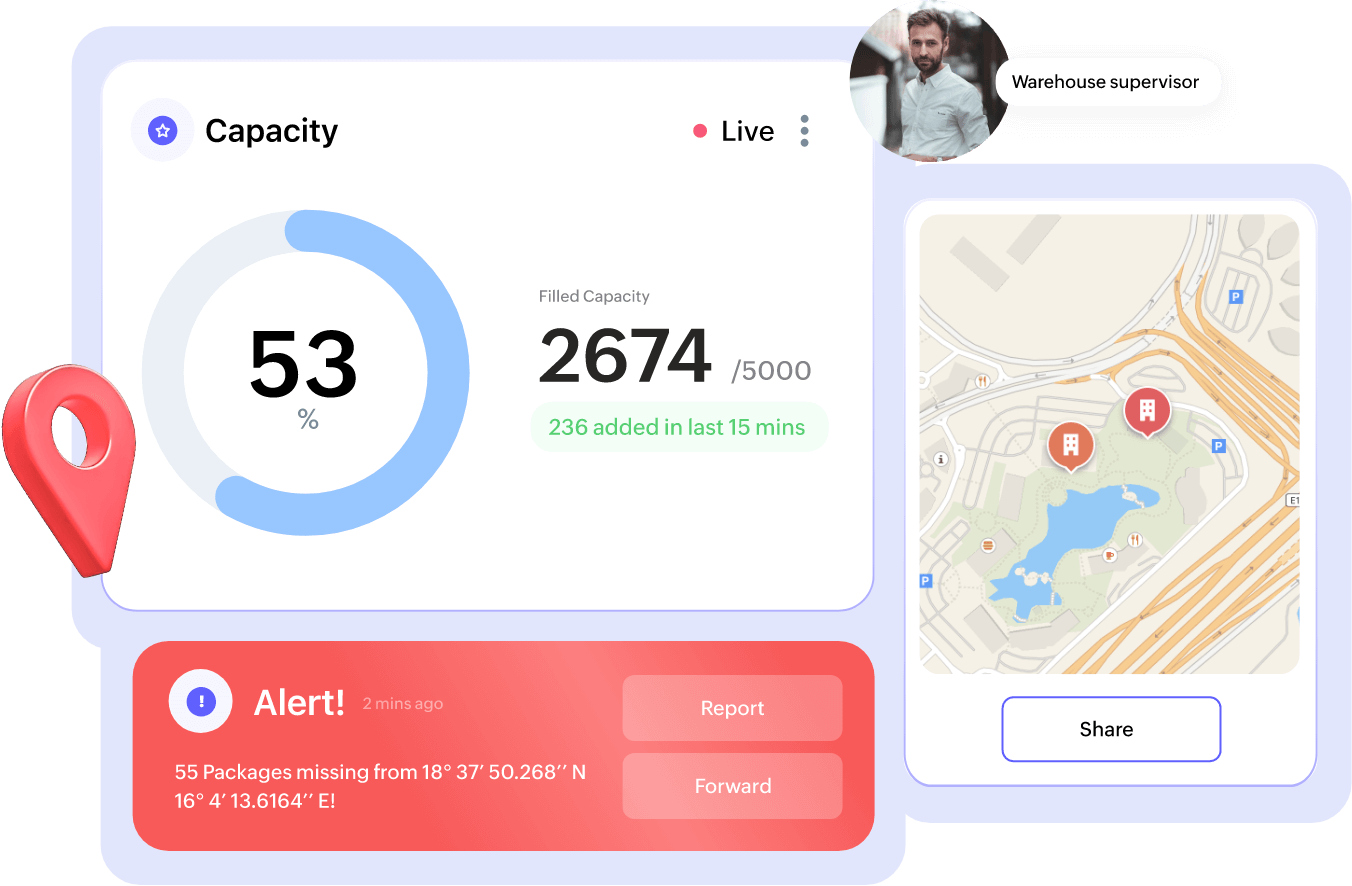

- Asset and Inventory Tracking

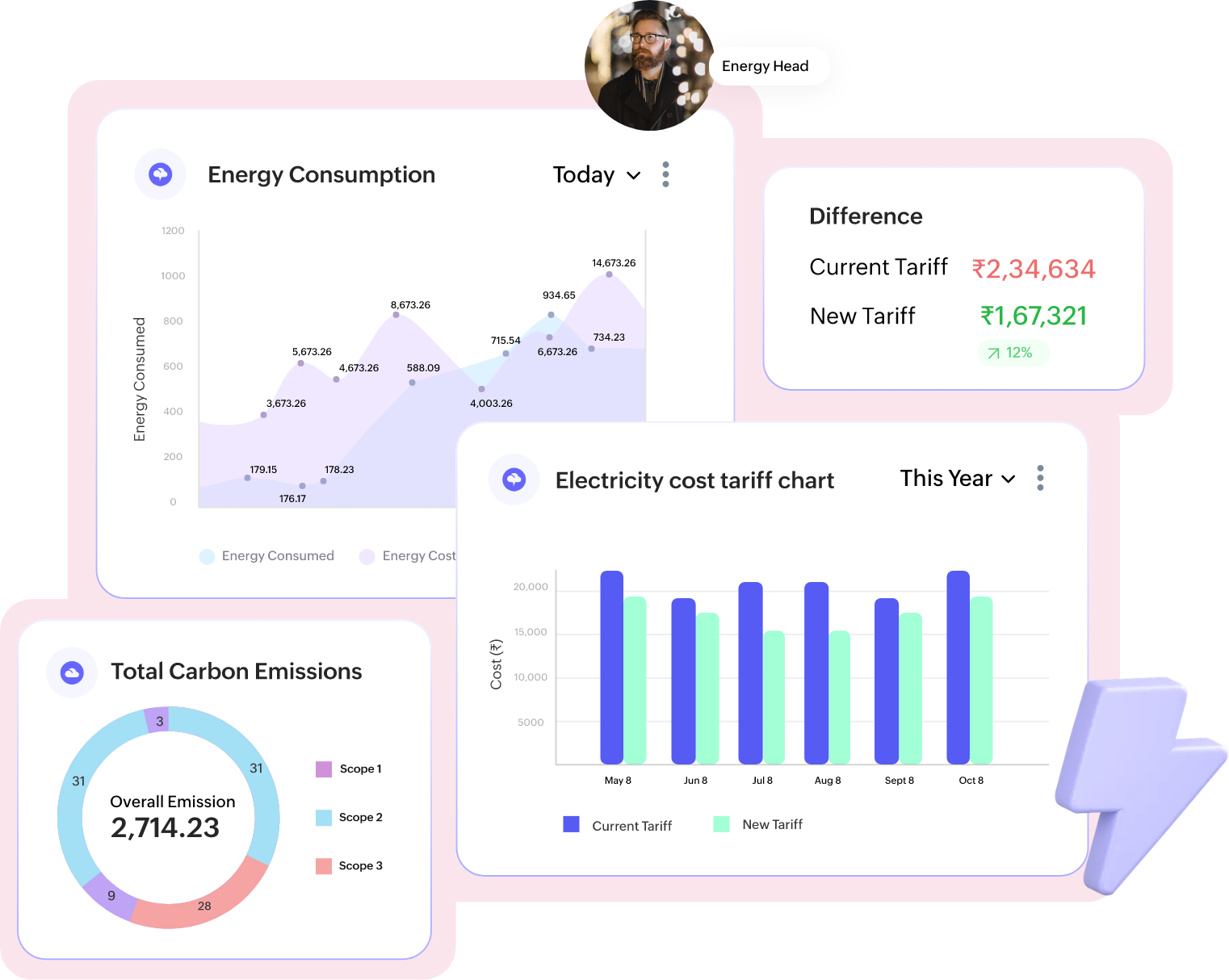

- Energy and Sustainability

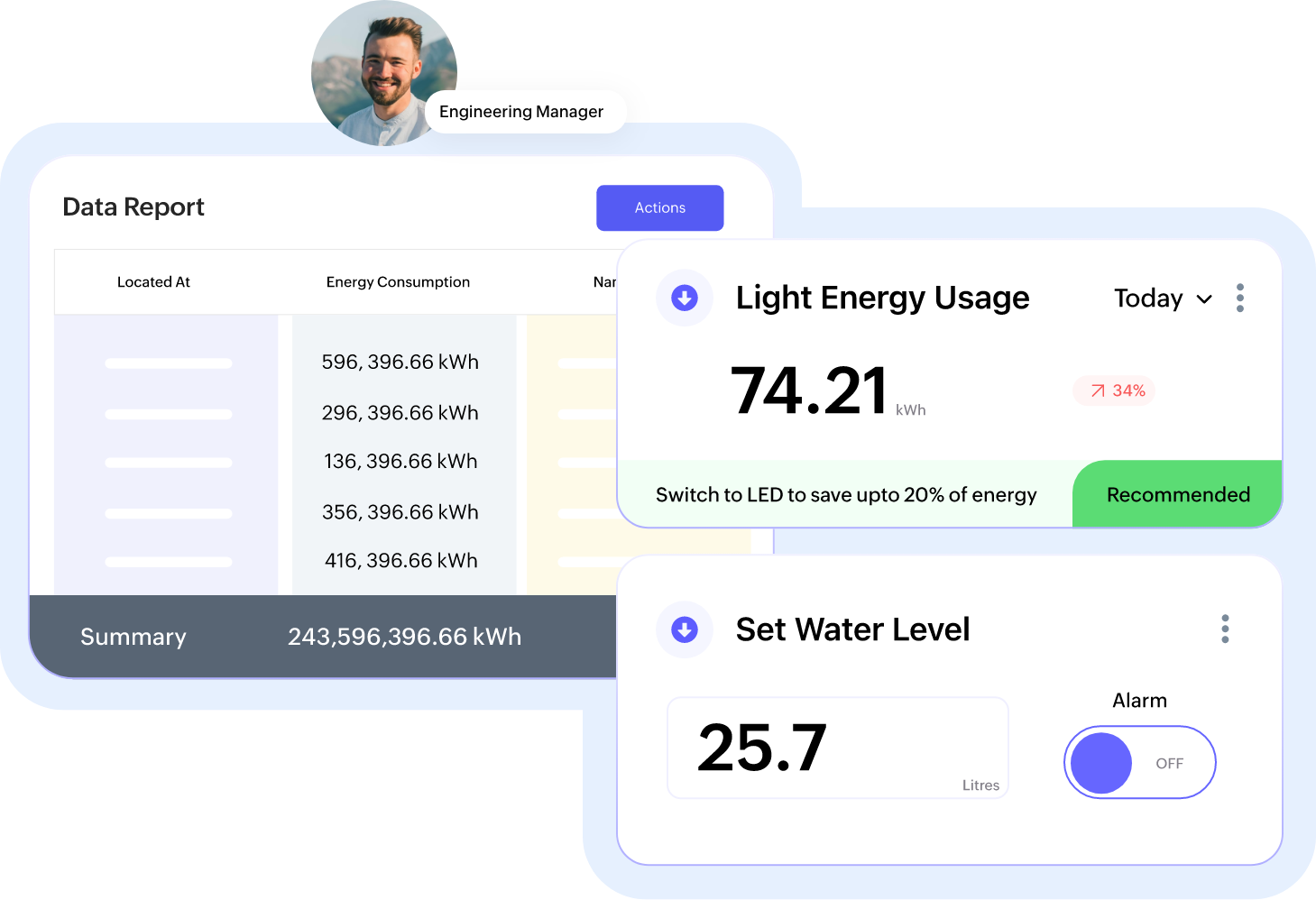

- Utilities Monitoring

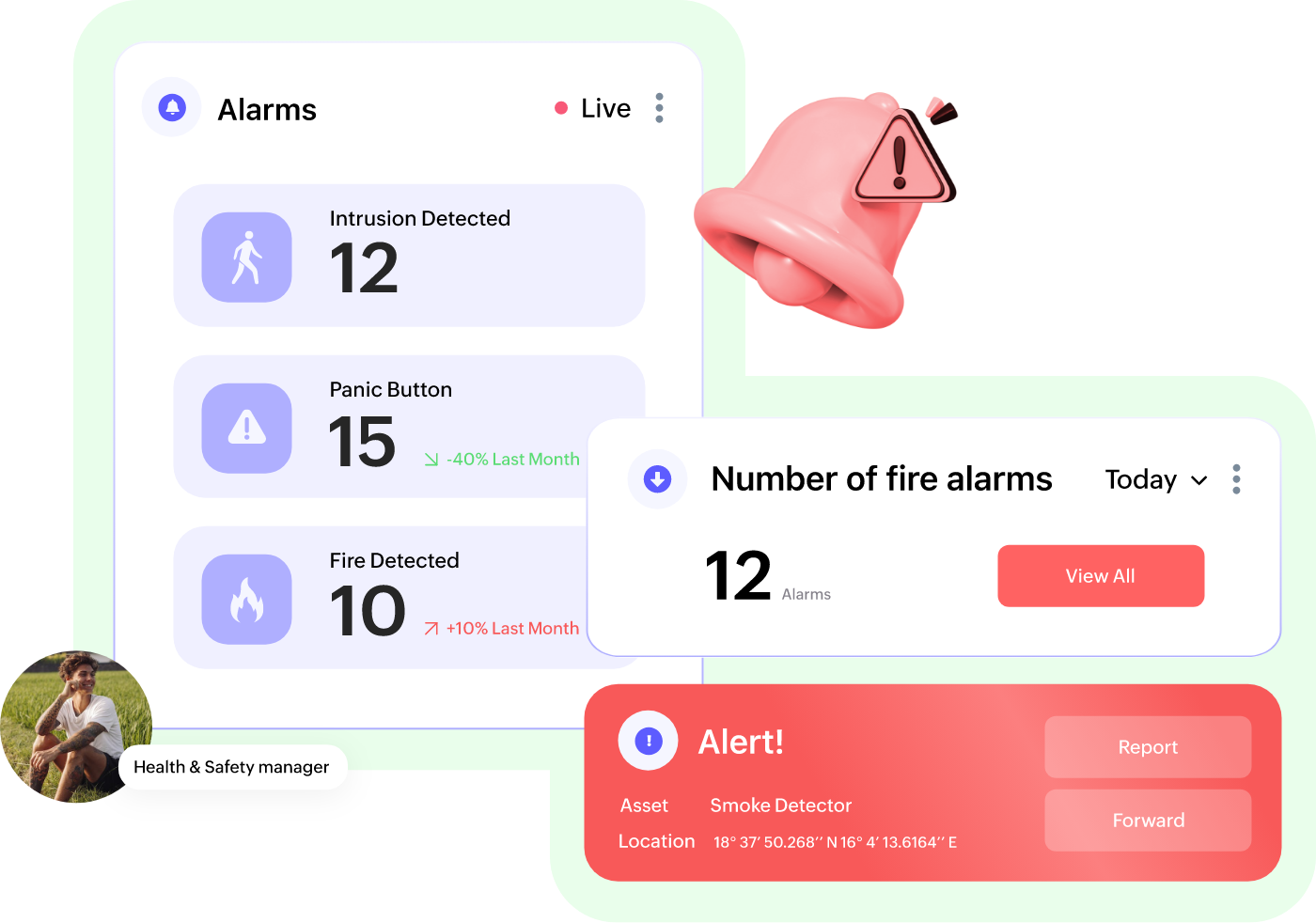

- Safety and Control

Single destination to achieve holistic shop-floor automation mastery

A detailed view of high-value assets

Monitor equipment ( CNC, robotic arm, SWISS, precision etc) in real time to maximize efficiency.

Condition monitoring

Access real-time data on the health and performance of industrial equipment.

Machine performance

Analyze speed, output, energy consumption, and health indicators to optimize performance.

Machine uptime/downtime

Monitor intervals when the machine is operational (uptime) and non-operational (downtime) to minimize disruptions.

Machine utilization

Measure actual operation time against scheduled available hours to optimize production schedules.

Asset operations

Monitor real-time asset performance.

Usage patterns

Analyze machine usage patterns for optimized shift allocation and performance.

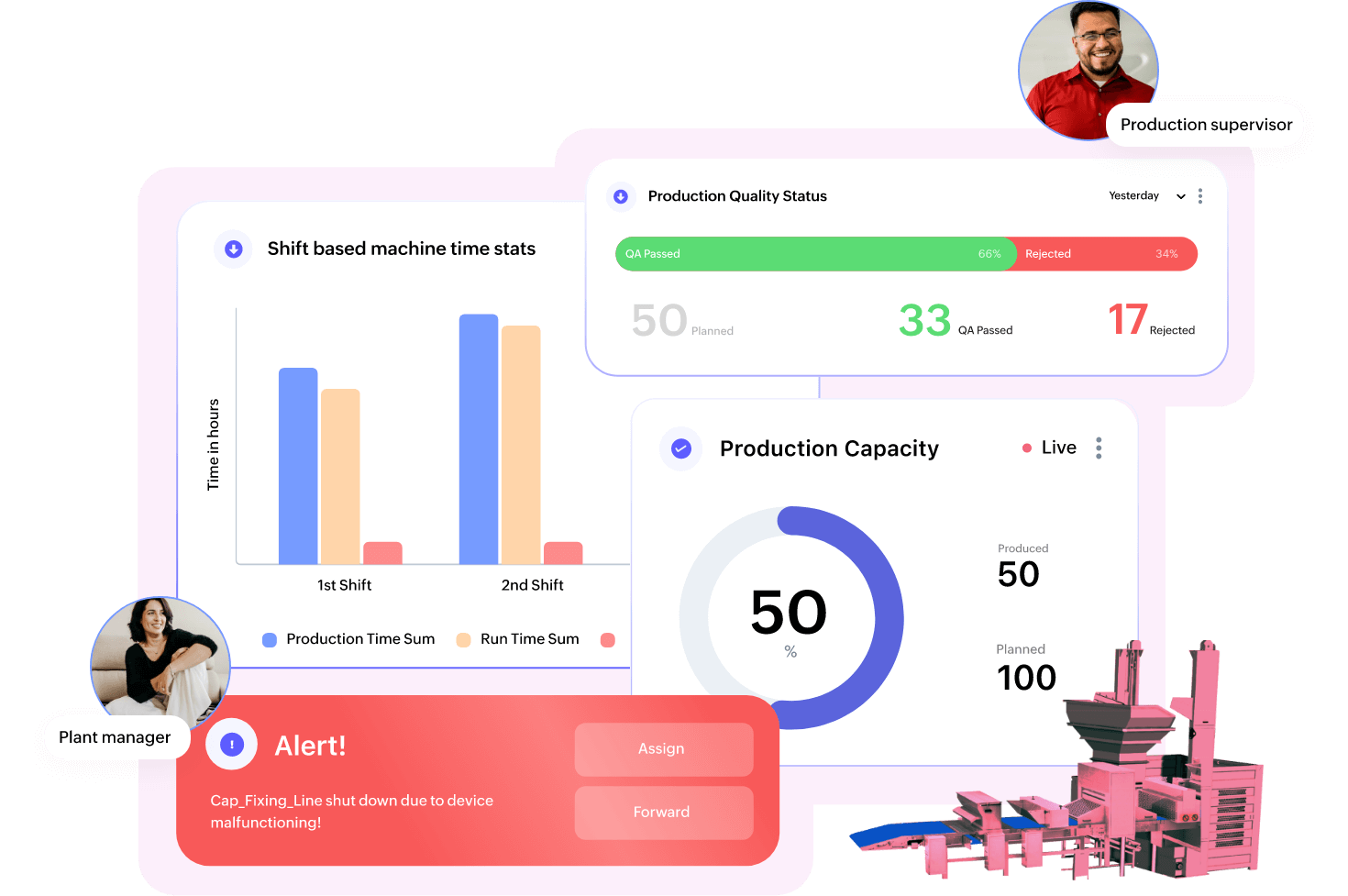

Reduce downtime and stoppages for production efficiency

Proactively monitor operations for enhanced productivity and quality control.

Line stoppages

Gain insights into the cause, duration, and frequency of interruptions.

Cycle time

Analyze the time to task completion to identify bottlenecks and optimize workflows

Planned vs actual yield

Compare projected and actual outputs to assess the effectiveness of production planning and enhance overall yield and efficiency.

Reject rate

Assess the percentage of manufactured products or components that do not meet the specified quality standards and take corrective action

Production downtime

Gain insights into the reasons for interruptions, their duration, and their impact on overall operational efficiency

Operator efficiency

View operator activities, performance metrics, and task completion rates to enhance productivity.

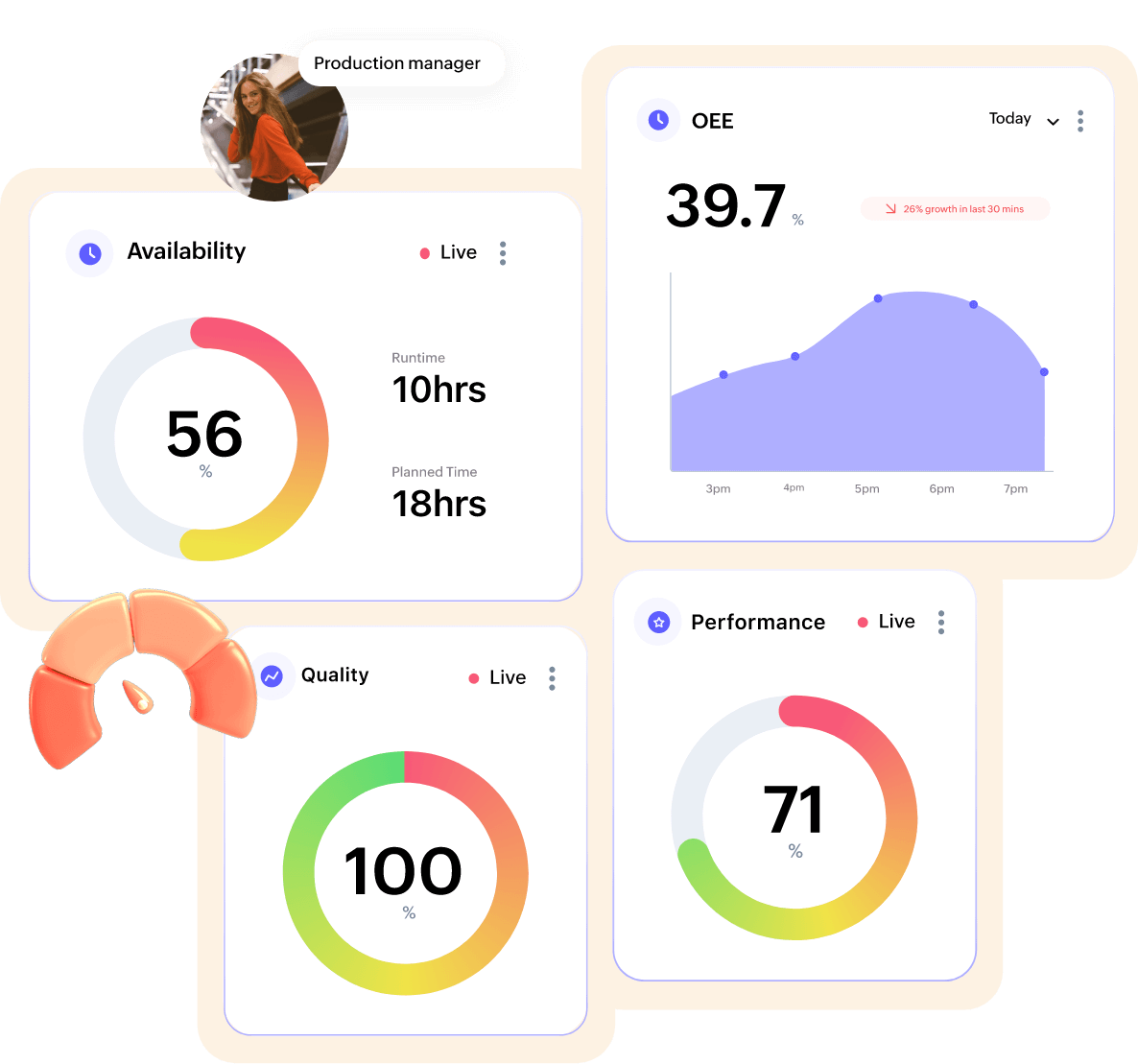

Evaluate OEE for greater productivity

Assess availability, performance efficiency, and quality yield.

Equipment effectiveness

Determine the availability, performance, and quality of industrial equipment.

Production bottlenecks

Identify process constraints and slowdowns.

Benchmarking

Compare OEE of industrial equipment with established standards to identify areas for improvement and set performance targets.

Asset performance

View real-time data on the health, condition, and usage of assets.

Productivity

Optimize workflows and energy efficiency by assessing industrial operations and output.

Availability

Track assets that are operational and ready for use to plan scheduled maintenance and avoid unplanned downtime.

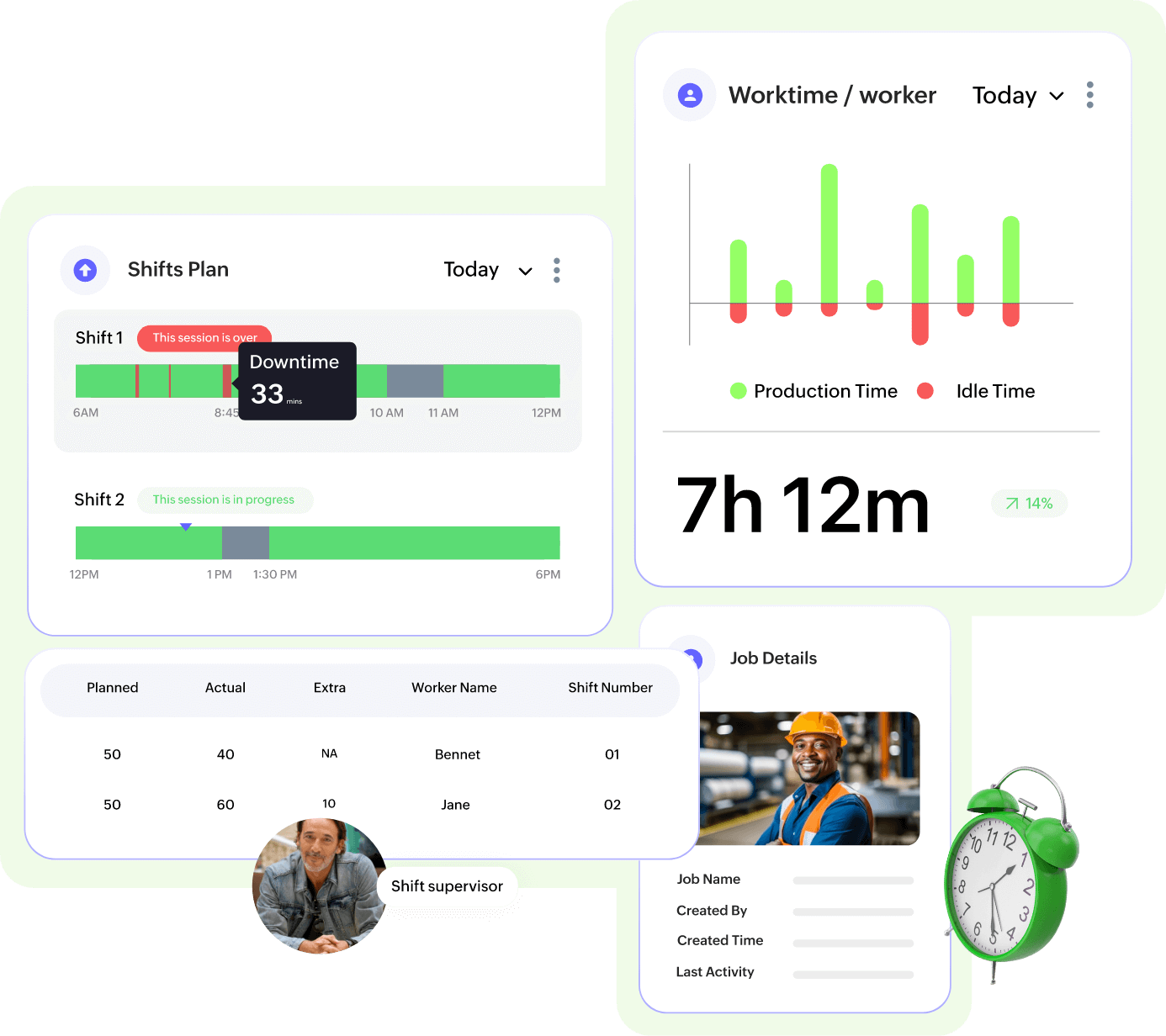

Keep track of shifts, jobs, and resources

Ensure optimal coordination of employee and equipment shifts based on energy consumption and productivity.

Real-time shift data

Continuous monitoring, analysis, and reporting of operational data during work shifts.

Resource allocation

Distribution and optimization of resources, such as personnel, machinery, and materials.

Job cards

Digital records that contain detailed information about a specific task, job, or work order to enhance visibility and streamline operations.

Shift scheduling

Automation of work shifts for personnel and machines to optimize resource deployment.

Time and attendance management

Tracking of employees' work hours and attendance to enhance productivity and ensure compliance.

Workforce efficiency

Insights for enhancing overall productivity and paving the way for collaboration.

Production planning

Coordination of resources, tasks, and schedules to achieve targets.

Idle time vs. productive time

Analysis of machine idle time and productive time to enable timely interventions and predictive maintenance.

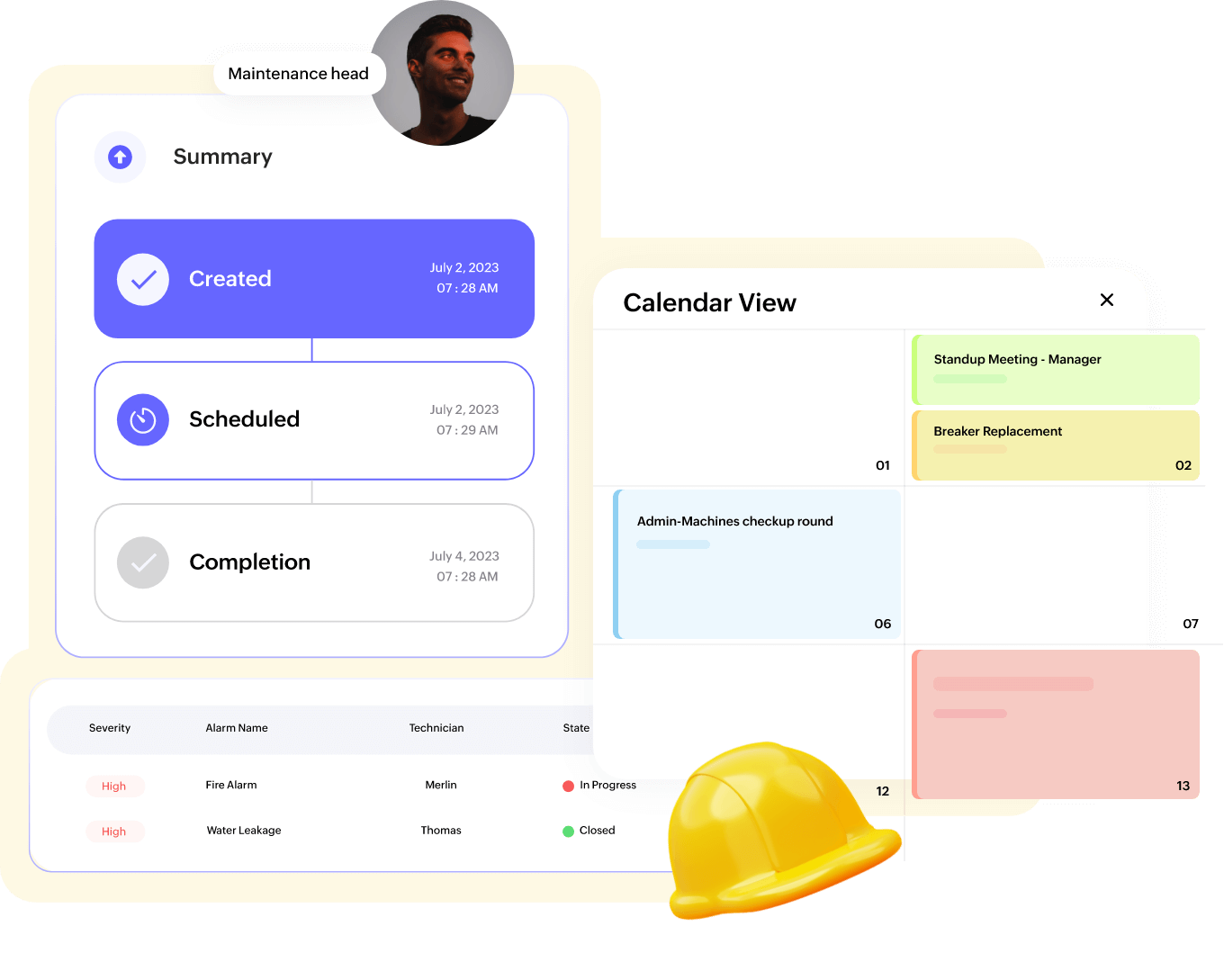

Perform condition monitoring, predictive maintenance, and work orders

Automate tasks quickly and reduce maintenance costs with Zoho IIoT. Detect early signs of downtime and schedule maintenance proactively.

Remote asset condition monitoring

Analyze real-time data on the health and performance of industrial assets from any location.

Predictive maintenance

Proactively prevent equipment failures and extend the life span of assets.

Mobile work orders

Digitally access detailed work instructions, asset information, and task assignments.

Scheduled/planned maintenance

Proactively schedule maintenance based on machine health to improve reliability, operational efficiency, and cost-effectiveness.

Maintenance history

Document maintenance activities to optimize production.

Asset repository

Access a comprehensive view of your assets, so you can make data-driven decisions and optimize maintenance strategies

Asset lifecycle management

Manage industrial assets end-to-end for their entire lifecycle, from acquisition and installation to operation, maintenance, and eventual decommissioning or replacement

Approval automation

Enable workflow automation, user authentication, conditional approvals and more.

Roles and authorization

Define and manage the access levels and permissions of individuals or entities.

Meet standards with precision

Create quality benchmarks and implement safety measures while ensuring regulatory compliance with ISO standards, FDA regulations, and ITAR.

Equipment health

Enable real-time monitoring of the condition and performance of machinery

Production yield

Measure the quantity and quality of industrial process output (relative to input).

Traceability

Track and record product production history, making it easier to identify and address quality issues

Compliance with regulations and standards

Build trust and minimize legal and regulatory risks.

Material composition

Accurately monitor the composition of materials to ensure quality standards are met.

Defect analysis

Analyze abnormalities in production to reduce waste and improve operational efficiency

Trace assets and stock from source to shelf

Access real-time insights and comprehensive visibility to prevent theft or loss,and maximize asset usage.

Asset identification

Gain enhanced visibility of assetsand perform maintenance as needed.

Location tracking

Track the location of assets with GPS, BLE, RFID and more to improve logistics and enhance safety

Availability

Monitor stock availability to reduce the risk of stock-outs or overstocking, enhance the order fulfillment processes, and improve overall supply chain efficiency.

Maintenance and service history

Document all maintenance and service activities to optimize production and resource allocation

Utilization analysis

Optimize the usage and management of industrial inventory for accurate order fulfillment and reduction of holding costs.

Geo-fencing

Use location-based technology to create virtual boundaries or geographical zones and trigger specific actions when industrial assets, equipment, or personnel enter or exit predefined areas.

Optimize energy consumption and reduce carbon emissions

Monitor and control energy consumption by industrial infrastructure equipment (HVACs, DGs, AHUs, Chillers, Compressors, and more) and production machines.

Energy consumption pattern

Take a data driven approach to improving energy efficiency, reducing operational costs, and achieving sustainability goals

Carbon emissions

Measure, track, and manage the release of carbon dioxide (CO2) and other greenhouse gases.

Waste generation

Access real-time insights into the volume and types of industrial waste you create and reduce your environmental impact.

Renewable energy integration

Integrate renewable energy sources with your existing layout.

Environmental conditions

Measure your site's air quality, noise, temperature and more.

Measurement and verification

Measure and verify the performance and efficiency of industrial processes to validate energy savings, process improvements, and other KPIs.

AI prediction and forecasting

Analyze historical and real-time data on energy consumption, demand, and production.

Unlock savings potential with smart utilities

Our solution acquires, manages, and reports vital data from power, water, and gas meters, such as voltage, velocity, pressure, and leakage.

Power quality

Track voltage stability, frequency, and harmonic distortion to maintain efficiency and prevent interruptions

Water usage

Monitor water consumption throughout facilities.

Gas flow and pressure

Measure the flow rates and pressure levels of gasses throughout facilities.

Leak detection

Detect water leaks or anomalies, preventing water waste and minimizing your environmental impact.

Demand planning

Monitor real-time energy consumption patterns and fluctuations.

Fault management

Proactively monitor, detect, and correct anomalies.

Remote monitoring

Monitor energy usage and consumption from any location.

For safe and secure manufacturing operations

Continually monitor fire safety equipment (such as fire extinguishers, fire alarm systems, and sprinkler systems).

Sprinkler system status

Monitor the status of the sprinkler system to ensure proper functioning and readiness.

Emergency sirens and lighting

Detect emergencies and enable sirens and lighting changes to notify tenants.

Temperature monitoring

Monitor anomalies in temperature.

Remote monitoring

Monitor abnormalities from any location.

Extinguisher status:

Track availability and status of fire extinguishers to ensure safe and timely fire intervention.

Smoke sensor detection

Detect smoke and notify tenants of abnormalities

Make your machines and processes efficient with real-time factory insights

Determine the cause & effect, and improve efficiency & predictability

Deliver unprecedented visibility on Machine-wise/Shop-wise/Building-wise energy, health and usage parameters, machine status, production/assembly line performance, maintenance and analytical insights.

Harness the potential of your manufacturing operations

Increase

- Asset life cycle

- Machine efficiency

- Revenue

Improve

- Operator retention

- Machine performance

- Quality of product

Optimize

- Machine utilisation

- Maintenance cycles

- Production

Transform

- Your Business

- Manufacturing operations

- workforce efficiency

Reduce -

- Downtime

- Energy consumption

- Maintenance and replacement costs

Envision, Unite, Prosper

We believe that the key to a successful industrial transformation is a collaborative partner ecosystem. Zoho's ecosystem consists of partners with distinct skills who can generate incremental value for customers in the discrete manufacturing sector.