- HOME

- Know Your Tech

- Streamlining manufacturing workflow automation with smarter tools

Streamlining manufacturing workflow automation with smarter tools

- Last Updated : October 29, 2025

- 242 Views

- 5 Min Read

Every hour of unplanned downtime is costly—especially when teams are already stretched thin. That’s why the plants leading today aren’t just more automated; they’re more human‑centric.

Often called Manufacturing 5.0, the idea is simple: Let software handle repetitive capture, routing, and hand-offs, so people can focus on exceptions, improvements, and judgment calls. With that lens, it’s easier to see where workflow automation helps most.

A manufacturing workflow is the connected sequence of tasks that gets a product from raw material to shipment—from inventory intake and production scheduling to in‑process checks, packaging, and dispatch. When those steps rely on paper, spreadsheets, or tribal knowledge, teams spend time chasing information instead of moving work forward.

What is manufacturing workflow automation?

Manufacturing workflow automation uses software to capture data, validate steps, route approvals, and update systems automatically. It isn’t “set‑and‑forget” robotics; it’s human‑in‑the‑loop orchestration. The right setup reduces errors, shortens cycle times, and gives line leaders real‑time visibility without adding admin overhead.

Some typical outcomes you can measure include:

Fewer hand-offs and faster approvals (minutes instead of hours).

Less rework through in‑flow checks and standardized capture.

Higher on‑time dispatches with scan‑to‑pack and automated documents.

Common bottlenecks in traditional manufacturing workflows

Manual data entry and duplicate typing across systems.

Missing genealogy, difficulty tracing lots/serials across steps.

Unclear ownership of exceptions, issues bounce between teams.

Delayed maintenance response when alarms aren’t triaged.

Paper trails that break during audits or recalls.

These slowdowns don’t just cost time; they hide problems. Automation surfaces issues sooner and makes the resolution path explicit.

How automation enhances the manufacturing workflow process

Below are practical ways automation strengthens each phase—mapping the process, applying targeted use cases, and choosing a platform that supports operators as much as systems.

Mapping the manufacturing process workflow

A simple map clarifies what to automate first. Start by listing key stations and handoffs, then the steps with the highest rework, wait time, or cost. A typical flow includes:

Design and prototyping: Capture revisions, approvals, and change notes in one place.

Production: Record inputs/outputs by station; link work orders to machine IDs.

In‑process quality: Enforce checks with validation rules; block downstream steps on hard fails.

Packaging and distribution: Scan‑to‑pack; auto‑generate ASN/invoice from the same master record.

Keep the first slice thin; just the minimum forms, the minimum rules, one operator view, and one KPI you’ll move (e.g., first‑pass yield or MTTR).

Turning maps into action with the right tools

A practical approach is to line up a few core capabilities against your high-impact steps, then pilot a thin slice.

Capabilities to prioritize

Data capture at the point of work: Forms, barcode/QR scans, photos, and checklists.

Validation and rules: Pre-checks, sign-offs, and exception handling that block bad hand-offs.

Orchestration and escalation: Workflows, notifications, and SLAs that move work to the right person.

Operator experience: Mobile (including offline), scan-first, role-aware screens for the line.

Integration and sync: REST APIs/webhooks to ERP/WMS/PLCs so systems stay aligned.

Governance and compliance: Role-based access and audit trails for who-did-what-when.

Reporting and KPIs: Real-time boards and alerts tied to MTTR, first-pass yield, and dispatch accuracy.

Start with the minimum forms, the minimum rules, one operator view, and one KPI you’ll move. When the pilot works, extend sideways—more stations, rules, and integrations.

The role of platforms like Zoho Creator

Zoho Creator helps you deliver those capabilities quickly, then improve them as you scale.

How Zoho Creator maps to the capabilities

Capture: Build forms fast; use native barcode/QR fields; attach photos from mobile.

Rules and exceptions: Model validations and approvals with Deluge workflows.

Orchestration: Route tasks, trigger notifications (SMS/email), and enforce SLAs.

Operator UX: Responsive web and mobile apps out of the box, with offline capture.

Integration: Connect via REST APIs, webhooks, and prebuilt connectors to your systems.

Governance: Role-based access and audit logs to meet audit/compliance needs.

KPIs: Kanban/board views and dashboards to track MTTR, FPY, and on-time dispatch.

Use cases of workflow automation in manufacturing

You can pilot three field‑tested plays quickly:

Predictive and digital maintenance: Convert sensor thresholds into auto‑classified work orders, notify the on‑shift technician, and track MTTR/MTBF with an audit trail.

Traceability and e‑records: Capture the lot/serial at each step via barcode/QR; enforce sign‑offs and generate time‑stamped records for faster audits and recalls.

Dispatch accuracy and customer visibility: Scan‑to‑pack with hard errors on mismatches; create ASN/invoices automatically; share order status via a secure portal.

Each use case strengthens a specific KPI and makes exceptions visible so teams spend less time searching and more time fixing.

Choosing the right manufacturing workflow software

When evaluating platforms, prioritize operator experience, time‑to‑value, and openness. The goal is a fast pilot that scales without lock‑in.

Key features to look for

Line‑side usability: Handheld‑friendly, scan‑first, and tolerant of spotty connectivity.

Fast to pilot: Can you ship a working slice in under 30 days with clear KPIs?

Exception handling: Validation rules, approvals, and escalation paths baked in.

Auditability and security: Role‑based access; who‑did‑what, when.

Integration: REST APIs/webhooks to connect upstream/downstream systems.

How Zoho Creator stands out

Build quickly with forms, reports, Deluge workflows, and reusable components—then harden with approvals and audit logs.

Create once, use on both the web and mobile; capture data where the work happens, even offline.

Use native barcode/QR fields for scan‑to‑save on the line.

Connect to your stack through APIs, webhooks, and prebuilt connectors.

Real-world success story: Ralpro’s custom ERP

The challenge

A fast‑growing aluminum extrusion business faced dispatch errors, manual paperwork, and limited visibility for customers. Scaling volume without sacrificing accuracy required tighter control at packing and clearer order status.

The solution

A custom ERP on Zoho Creator provided QR‑based package control, scan‑to‑pack validation, automated invoices, and a secure customer portal. Role‑based access and audit trails improved accountability across shifts.

The results

Monthly dispatch scaled from ~180 tons to ~440 tons within the year.

Dispatch and billing errors were eliminated through scan‑first checks.

Overall productivity improved by 5× as paperwork and rework dropped.

Why customization is critical

No two plants run the same workflows. Low‑code lets you model real‑world exceptions—rework loops, quarantines, alternate routing—without forcing a one‑size‑fits‑all process. As needs evolve, you can add rules, stations, and portals without rebuilding the core.

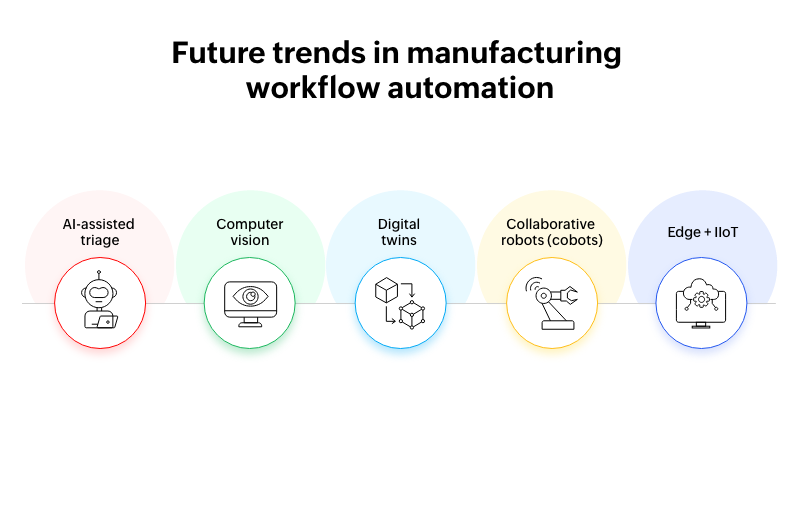

Future trends in manufacturing workflow automation

Looking ahead, the shift is less about more automation and more about better collaboration between people and systems.

AI‑assisted triage: Route maintenance based on risk and context.

Computer vision: Inline defect detection triggers immediate checks.

Digital twins: Simulate changes before deploying to the line.

Collaborative robots (cobots): Operators handle exceptions; robots repeat precise tasks.

Edge + IIoT: Capture machine signals locally and sync to apps built on Creator.

Integration with software platforms

The best results come when workflow apps connect cleanly to ERP, quality systems, and WMS. APIs and webhooks keep master data aligned while letting operators work in purpose‑built, lightweight interfaces.

Why businesses must prepare now

Talent is tight, expectations are rising, and downtime is expensive. The most resilient manufacturers are shipping small, focused apps that move one KPI at a time—then scaling what works.

Conclusion

Manufacturing workflow automation isn’t about replacing people. It’s about giving teams better tools so work moves faster, errors drop, and change is safe to deploy. With a human‑centric approach and a platform like Zoho Creator, you can start small, prove value, and expand confidently.

If you’re ready to explore a pilot on your data, start with a thin slice—one line, one KPI, four weeks—and build from there.

Pranesh

PraneshPranesh is a serial entrepreneur and the Founder of Studio 31, a 12 year old, deep tech enabled, wedding photography and film company that has been recognized by many publications for its zero inventory model and unique culture in the unorganised sector.

Zoho Creator has helped Studio 31 redefine its business model by automating over 37 processes and save three hours every single day. He is also a growth consultant for Zoho Creator and helps the team address real-world challenges from a customer's point of view.