- HOME

- Know Your Tech

- Understanding operations management: Key concepts and insights

Understanding operations management: Key concepts and insights

- Last Updated : October 30, 2025

- 297 Views

- 10 Min Read

Whether you're managing operations at a seed-funded startup or an established enterprise, the goal remains the same: run your business efficiently, save costs, and make the best use of resources. The global operational technology market, valued at $210.06 billion in 2024, is projected to reach $364.74 billion by 2030, growing at a CAGR of 9.6% from 2025 to 2030.

Keeping expenses under control and using resources wisely is essential for business growth. Operations management provides the strategies to achieve this by improving the processes that keep everything running.

In this blog post, we’ll cover the core concepts of operations management, the key skills you’ll need, and how the right techniques can help you reduce costs, overcome challenges, and meet your goals.

Highlights:

- Operations management improves efficiency by optimizing processes, supply chains, and quality control.

- KPIs like uptime, throughput, and error rates track performance and highlight inefficiencies.

- Automation and analytics speed up workflows, cut costs, and improve customer satisfaction.

- Low-code platforms like Zoho Creator help businesses build custom apps, automate processes, and integrate systems for growth.

What is operations management?

Operations management is the practice of ensuring that goods and services are produced and delivered efficiently and in line with customer needs. Initially focused on manufacturing, this discipline now applies across industries to optimize performance and reduce costs.

The global market for manufacturing operations management software, valued at $15.89 billion in 2023, is expected to grow to $52.5 billion by 2032 at a CAGR of 14.2%. This growth highlights the role of technology in making operations management a core driver of business success.

To make operations management effective in your organization, the first step is to grasp the underlying principles that guide it. These principles form the foundation for improving efficiency, managing resources, and consistently meeting customer expectations.

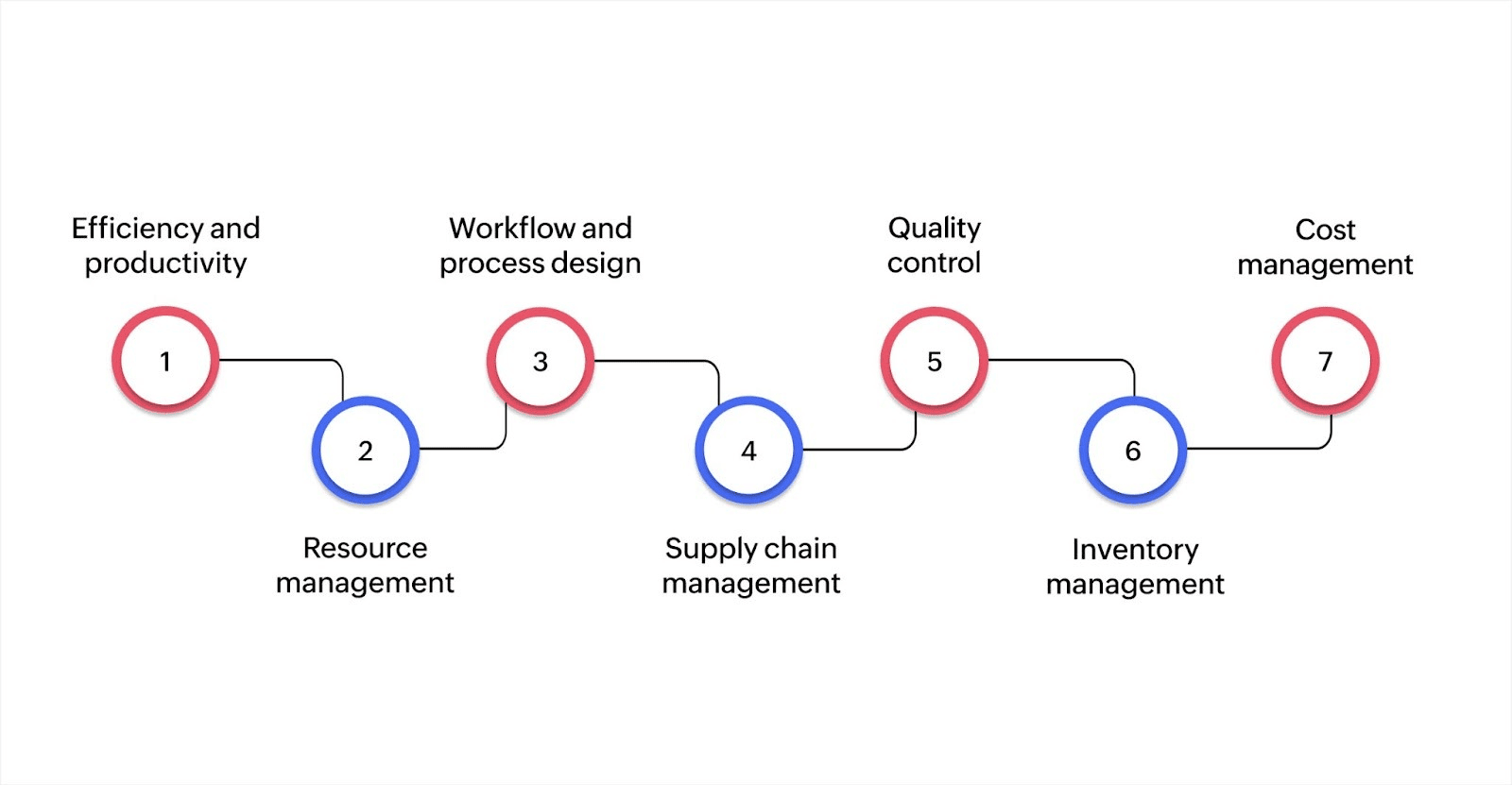

What are the core operations management concepts?

Each concept addresses a specific aspect of running your business, and together, they create a complete system for effective operations.

1. Efficiency and productivity

Efficiency means getting the most output from your inputs without waste or delays. Productivity measures how much you produce relative to the resources you use. These two ideas work together to help you deliver products or services faster and cheaper while maintaining quality.

Example: An online store processes orders through five steps involving three different people. Combining tasks and reducing handoffs so one person can verify payment, print the shipping label, and update inventory in a single workflow can reduce processing time.

Implementation tips:

- Map current processes: Document each step in your key workflows, noting time spent, people involved, and tools used to identify where delays and waste occur.

- Remove steps that add no value: Look for approval steps, handoffs, or checks that don't directly improve quality or speed, then test removing them one at a time.

- Measure key metrics: Track cycle time, output per hour, and resource utilization weekly to see whether changes actually improve efficiency. With Zoho Creator, you can build custom dashboards that automatically calculate and display these metrics in real time.

2. Resource management

Resource management assigns the right people, materials, and equipment to the right tasks at the right time. Poor allocation shows up as people sit idle while others are overwhelmed, materials arriving too late or too early, or equipment breaking down due to lack of maintenance.

Example: A consulting firm faces fluctuating project demands across different clients and service lines. Tracking who's working on what and when projects end allows the operations manager to schedule new projects right when consultants become available, keeping utilization high without overloading anyone.

Implementation tips:

- Track availability and usage: Create a simple system to see who's working on what, what materials you have in stock, and when equipment needs maintenance.

- Plan ahead for peaks: Busy periods come at predictable times in most businesses, so schedule resources in advance and build buffer capacity for unexpected demand.

- Cross-train team members: Train people to handle multiple roles so you can shift resources flexibly when priorities change or someone is unavailable.

3. Workflow and process design

Workflow design creates the sequence of steps that turn inputs into finished outputs. Good workflows move work forward logically with clear handoffs, minimal delays, and no confusion about what happens next.

Example: Consider a customer support team that handles refund requests through multiple departments with approvals at each step. They redesign the process so agents can approve refunds under $50 directly without escalation, resulting in a significant drop in resolution time.

Implementation tips:

- Visualize the flow: Draw out your process steps in sequence, showing decision points, responsible parties, and handoffs to spot where work gets stuck.

- Reduce handoffs: Each time work moves between people creates a delay risk, so combine tasks when possible or create clear transition criteria.

- Build in feedback loops: Add quick checkpoints early in the process to catch errors before they become expensive to fix later.

4. Supply chain management

Supply chain management oversees the entire flow from sourcing raw materials to delivering finished products to customers. Every delay or problem in your supply chain affects your ability to deliver on time, which makes coordination and backup planning critical.

Example: A furniture manufacturer depends on wood suppliers for production. Working with three suppliers instead of one and tracking lead times carefully means that when the primary supplier has a delay, the company can order from alternates without stopping production. Ordering two weeks earlier than needed builds in buffer time for unexpected delays.

Implementation tips:

- Build supplier relationships: Communicate regularly with key suppliers about your needs and their capabilities to prevent surprises and get priority when capacity is tight.

- Create backup options: Identify alternative suppliers, shipping routes, or production methods you can activate quickly when your primary option fails.

- Track lead times accurately: Measure how long each supply chain step actually takes, not how long it should take. Then, use real data to plan orders and production.

6. Quality control

Quality control establishes standards for what good output looks like and checks that products or services meet those standards consistently. Building quality checks into each step catches problems early when they're quick and cheap to fix, rather than when defects reach customers.

Example: A warehouse fulfills online orders that require picking, packing, and shipping. By verifying item codes during picking, checking quantities while packing, and confirming addresses before shipping, staff can catch errors at each point. Finding a wrong item during packing takes seconds to fix, while discovering it after shipping requires costly returns and reshipments.

Implementation tips:

- Define clear standards: Document exactly what acceptable output looks like with specific criteria, measurements, or examples so everyone knows the target.

- Check early and often: Add quality verification at multiple points in your process, not just at the end, to catch problems when they're easiest to fix.

- Track defect patterns: Record what types of problems occur and where they originate to identify root causes and prevent recurring issues. You can use Zoho Creator to build quality tracking forms that capture defect data and generate reports showing patterns over time.

7. Inventory management

Inventory management monitors and controls the quantities of raw materials, work-in-progress, and finished goods you keep on hand. Too little inventory creates stockouts that delay production or disappoint customers, while too much ties up cash and takes up space.

Example: An ecommerce business sells phone accessories, where some products sell out while others accumulate excess stock. Tracking sales velocity for each item and reordering fast-moving items weekly, while ordering slow-moving items monthly, can reduce stockouts on popular products while avoiding overstock on slow sellers.

Implementation tips:

- Track inventory in real time: Use systems that update stock levels immediately when items arrive or ship so you always know what you actually have available.

- Set reorder points: Calculate the inventory level that triggers a new order based on lead time and usage rate to reorder automatically before you run out.

- Analyze inventory turnover: Measure how quickly inventory sells and identify slow-moving items you should discount or stop ordering.

8. Cost management

Cost management tracks expenses across procurement, labor, production, and overhead to ensure you're spending efficiently. Every dollar you spend on operations affects your bottom line, which makes knowing where money goes and finding ways to reduce spending without hurting quality critical.

Example: A restaurant has food costs higher than industry benchmarks with significant waste. Measuring how much food gets thrown away daily, standardizing recipes with exact portions, and training cooks to follow them consistently can reduce significant food waste without changing menu prices or quality.

Implementation tips:

- Track costs by category: Break down spending into materials, labor, overhead, and other categories to see where most money goes and where you have control. Zoho Creator allows you to build expense tracking apps that categorize costs automatically and show spending trends.

- Compare to benchmarks: Research industry standards for key cost ratios and compare your numbers to identify areas where you're spending more than typical.

- Find waste sources: Look for materials thrown away, time spent on rework, equipment sitting unused, or processes that take longer than necessary.

Note: These concepts apply whether you run a software company, retail store, or manufacturing plant. The specifics change, but the principles stay the same.

The concepts themselves are important to know, but their impact on your business goes deeper than you might think.

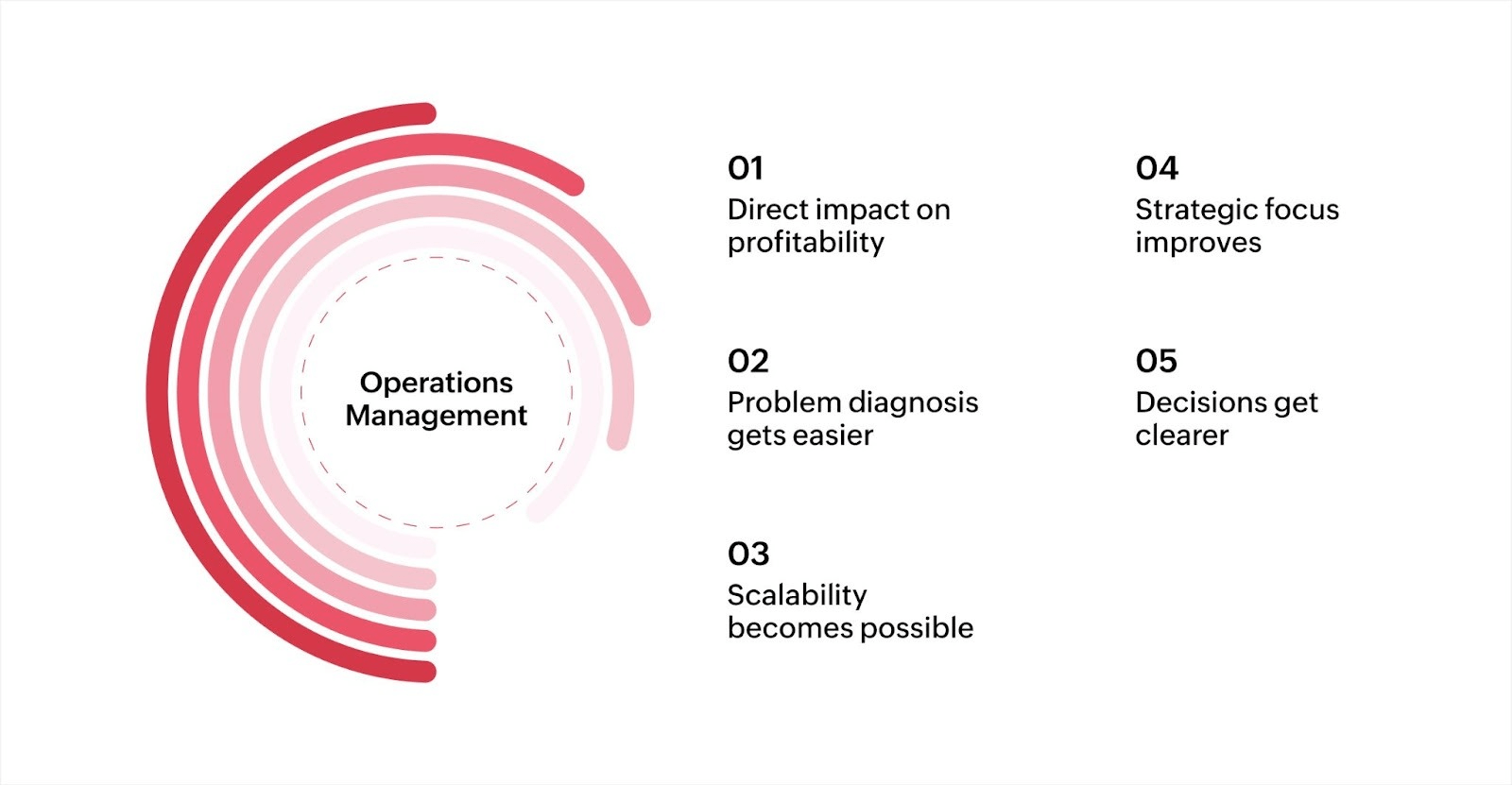

Why do operations management concepts matter?

Operations management concepts give you a framework to identify problems and make improvements. Without clear principles to guide decisions, you end up reacting to issues instead of preventing them.

Here's why applying these concepts creates real business value:

- Direct impact on profitability: Reducing waste, speeding up delivery times, and controlling costs directly improve your profit margins while increasing customer satisfaction.

- Problem diagnosis gets easier: When you're struggling with late deliveries, operations concepts help you identify whether the issue is workflow design, resource allocation, or supply chain coordination.

- Scalability becomes possible: Systems that work with five people can break down with fifty people unless you apply clear operations principles that handle increased volume.

- Strategic focus improves: When your operations run smoothly, you free up time and resources to focus on growth, innovation, and customer experience instead of constantly fixing problems.

- Decisions get clearer: When you face a choice between hiring more staff or redesigning workflows, operations concepts give you a framework to evaluate which solution addresses the root cause.

Each concept has value on its own, but the real gains come from how they influence and support each other.

How do operations management concepts work together?

Each concept connects to and influences others throughout your operations. Changes in one area create effects elsewhere, which means you need to think about how concepts interact.

Here's how concepts connect throughout your operations:

- Workflow design affects resource management: Processes with too many handoffs waste labor time waiting for approvals or information, which means simplifying workflows reduces the resources needed to complete tasks.

- Quality control influences cost management: Catching defects early in production costs less than fixing them after delivery, which means strong quality processes reduce rework, returns, and customer complaints that drain profit.

- Inventory management connects to supply chain management: Without accurate tracking of what you have, you can't order materials at the right time, creating stockouts that delay production or excess inventory that ties up cash.

- Process improvements create multiple effects: For instance, let’s say a furniture maker rearranges their shop floor so materials move in one direction through production. This single change reduces labor hours per piece, lowers work-in-progress inventory, and improves delivery speed all at once.

When you make operational changes, consider how they impact other areas to prevent unintended problems and maximize the benefit of improvements.

Tip: Start by identifying your biggest operational pain point. Then trace how it connects to other concepts to find the root cause, not just the symptom.

What challenges come with operations management?

Applying these concepts often reveals underlying issues that you need to address for improvements to stick. Knowing what to expect helps you plan solutions proactively.

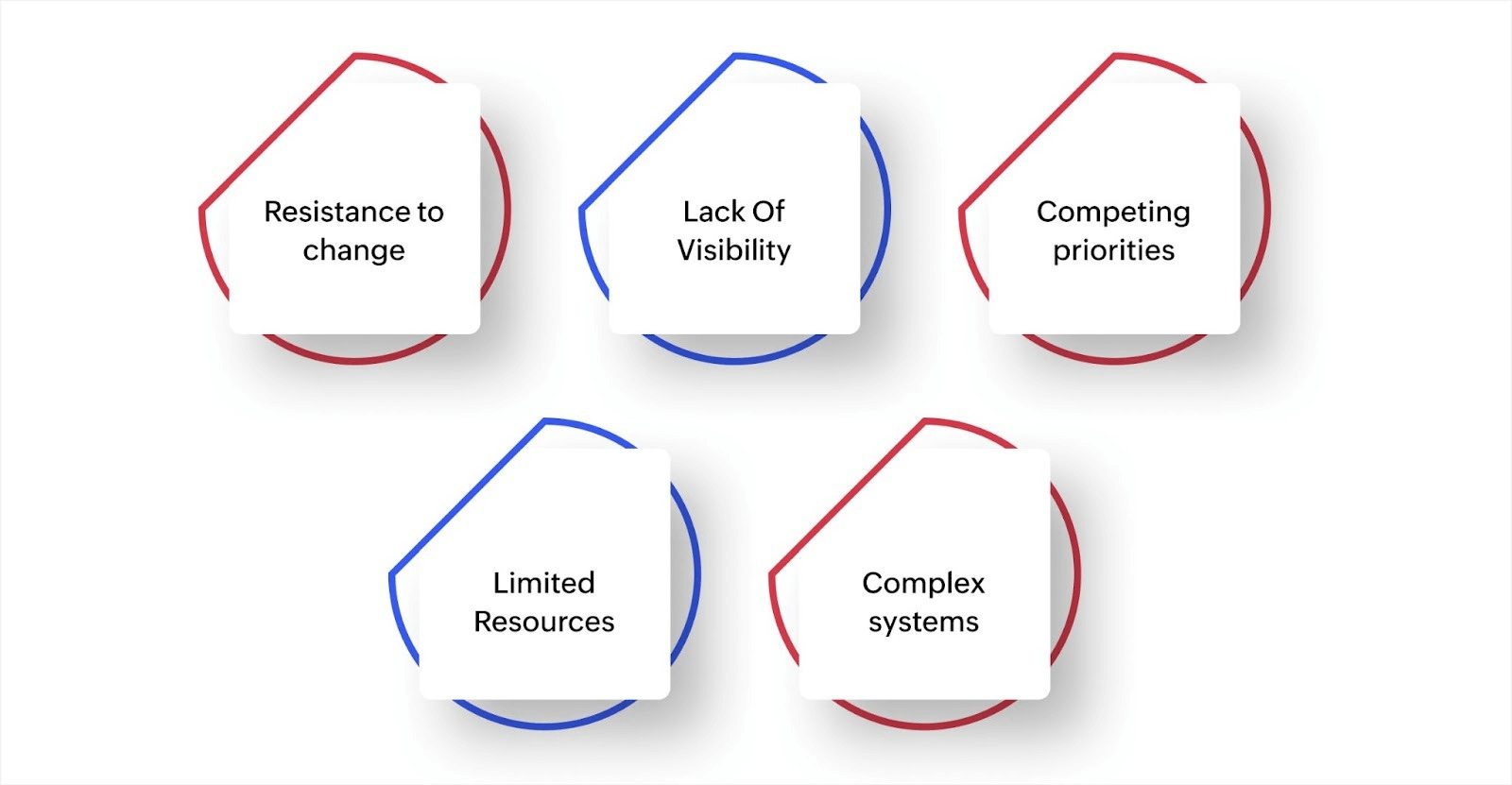

Common challenges include:

- Resistance to change: People prefer familiar ways of working, even when new processes work better. Address this by involving teams in the improvement process and explain why the changes will help them. When they see how a new workflow reduces frustrating delays, they're more likely to embrace the change.

- Lack of visibility: You can't improve what you can't see. Without data on cycle times, defect rates, or resource utilization, start by creating simple tracking systems. Basic spreadsheets or forms can capture information before building complex solutions.

- Competing priorities: Operations improvements compete with daily work. Assign dedicated time for improvement projects and protect that time from interruptions. Even one hour per week focused on process improvement creates meaningful progress over time.

- Limited resources: You might lack budget, people, or tools for large-scale changes. Start small by picking one concept and one process to improve. Success with small projects builds momentum and justifies investment in larger improvements.

- Complex systems: Operations with many dependencies feel overwhelming. Break complex systems into smaller pieces and improve one piece at a time. Small wins accumulate into significant operational gains.

The key is starting despite challenges. Waiting for perfect conditions means never improving. Begin with what you can control and build from there.

Build operations that scale using Zoho Creator

Manual tracking often creates errors and delays. You need systems that work as your operations expand.

Zoho Creator lets you build custom operations apps without complex coding. Create tools that fit your specific workflows, track the metrics you need, and adapt as your processes evolve.

Here's how it helps:

- Custom apps: Build apps that match your exact processes, not generic software that forces you to work differently than you need to.

- Automated workflows: Set up workflows that move tasks forward automatically, reducing manual handoffs and delays that slow operations.

- Form validation and approvals: Create forms with validation rules and approval workflows that ensure quality standards are followed every time.

- Cross-functional reporting: Combine data from multiple sources to generate reports that show exactly where money goes and how operations perform.

- Multi-device access: Apps run natively on web, iOS, and Android devices, so your team can access operations data whether they're in the office or in the field.

Operations management concepts give you all the effective frameworks. Zoho Creator gives you the tools to make them real.

FAQ

1. What is the difference between operations management and project management?

Operations management focuses on ongoing, repeating processes that deliver products or services continuously. Project management deals with temporary initiatives with defined start and end dates, specific goals, and unique deliverables.

2. Can you apply operations management concepts without specialized software?

You can start with spreadsheets and basic tracking, but specialized tools help you apply concepts more effectively as complexity grows. Software provides real-time visibility and automation that manual methods can't match.

3. How long does it take to see results from applying operations management concepts?

Simple workflow improvements can show results in weeks. More complex changes involving multiple concepts take months. Start with quick wins to build momentum, then handle larger improvements.

4. What metrics should you track when applying operations management concepts?

Track metrics relevant to your focus area. Common ones include cycle time, defect rate, on-time delivery percentage, resource utilization, inventory turnover, and cost per unit. Choose three to five metrics that reflect your improvement goals.

5. How do you know if your operations management is working well?

Good operations deliver products or services on time, meet quality standards consistently, operate within budget, and scale without breaking. Customer complaints are rare, and teams spend time on productive work instead of fixing problems.

Merlin

MerlinMerlin is our in-house digital workplace content specialist. She spends part of her days combining her passion for writing with marketing. The rest of her time is spent reading manga, battling friends in online games, and discovering new music.